As mit motorsports' lead expert on gd&t I was responsible for producing drawings for many of the MY24 car's systems to submit to machine shops for manufacturing. I created drawings for many intricate parts ensuring strict adherence to asme standards while tracking tight tolerance stack ups across multiple features. For my25 I am conducting trainings on GD&T standards and techniques for new members to produce their own drawings for out-of-house machining.

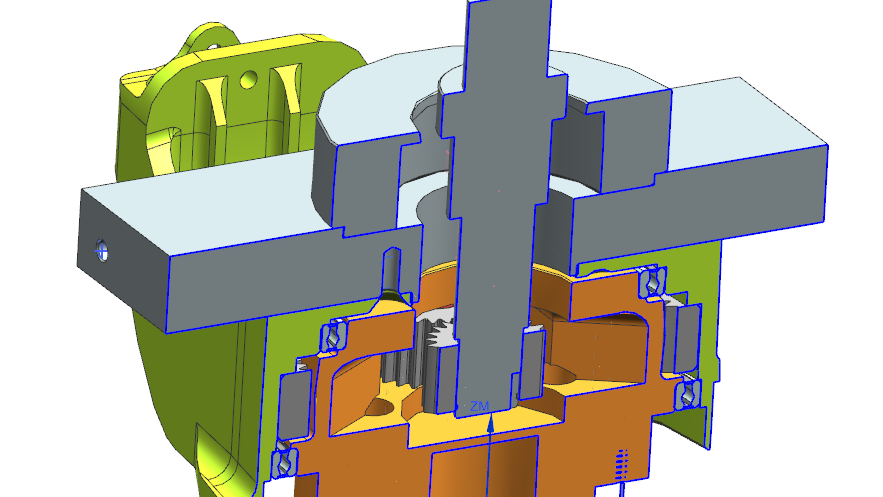

The following is the drawing for our rear suspension uprights. The drawing features tolerancing on many interaction features, such as the lower ball joint attachment point, camber adjust attachment point, brake caliper mounting points, and the press fit surfaces for the hub bearings. Mounting hole patterns are tightly constrained as any deviation could change the suspension geometry and negatively impact the suspension performance and response. The bearing press fit is also tightly controlled as the force on the bearing must be precisely controlled to keep it fully constrained while not deforming it, which would cause unnecessary friction costing efficiency and power.

The following is the drawing for the hubs that fit within the upright detailed above. These had special callouts for steel inserts in the threaded holes for our wheel studs. These inserts reinforced the strength of the threads as the studs undergo a significant force and the tiny threads through aluminum may have yielded. There is also a tight profile and positional tolerance on the back of the hub in the three C-shaped grooves. These were to fit with wire EDM machined steel inserts which bore the compressive load of the tripod half shafts that served as our driveshafts.

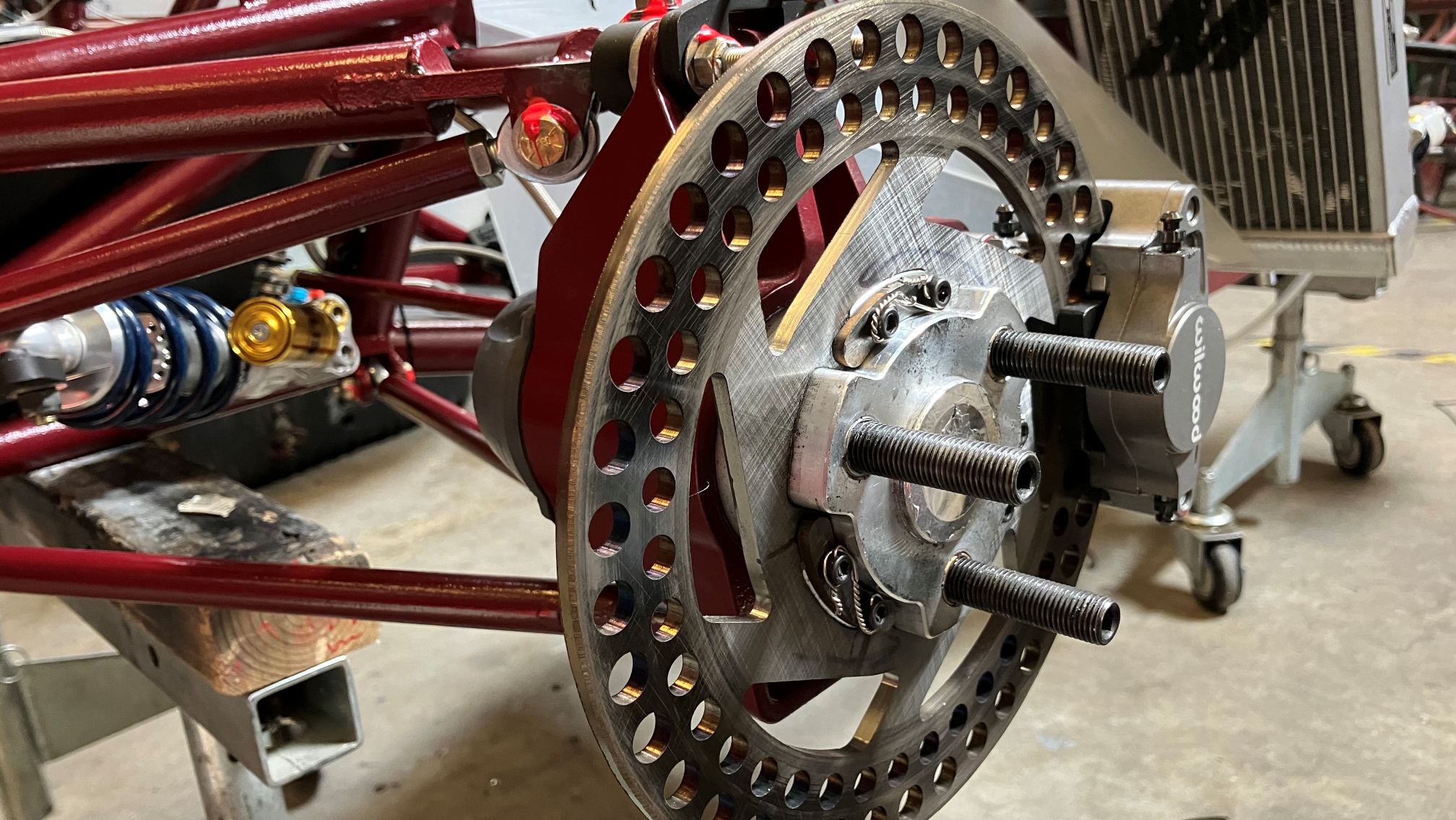

THIS WAS THE DRAWING FOR THE BRAKE ROTORS I DESIGNED. most IMPORTANT HERE WERE THE TOLERANCES ON THE MOUNTING TABS THAT INTERFACED WITH THE HUBS, AND THE PARALLELIZATION OF THE SURFACE OF THE ROTOR TO ENSURE NO OSCILLATION OR UNEVEN CONTACT DURING BRAKING. the TIGHT PARALLELIZATION WAS ACHIEVED THROUGH GRINDING THE ROTORS WITH A LOCAL SHOP AFTER THEY HAD BEEN RECEIVED FROM THE MACHINE SHOP THAT MANUFACTURED THEM.